Detala Produkta Priskribo

| Rapideco de Produktado: | 45m / min | Etiketa Precizeco: | ± 1mm |

|---|---|---|---|

| Etikedo Maksimuma Larĝo: | 190mm | Etikedo Interna Diametro: | 76.2mm |

| Etikedo Ekstera Diametro: | 330mm | Uzado: | Adhesive Labels Boteloj |

High Precision Dual Label wrap-around Labeling System for adhesvie label

Apliko

1 , the labeling machine is designed for putting two labels at a required spacing on to a round bottle with orientation requirement. It is widely used in the personal care product, food & beverage, health product and pharmaceutical product industries.

2, Etikedado de maksimuma larĝo estas 190mm (levebla laŭ la bezono)

3, Botela diametro: 30-100mm, Etikedo interna diametro estas 76,2mm, maksimuma ekstera diametro estas 330mm.

4, La aerprema pumpilo de aerfonto estas 4-6KG, ĉirkaŭ 30L / MIn.

5, It is specially designed to also fulfill the demanding requirement that when putting two labels on one bottle, the labels have to be symmetrically aligned on the bottle irrespective of the bottle diameter variation.

Teknikaj Parametroj

| Rapideco de produktado | 45m / min |

| Etikeda precizeco | ± 1mm |

| Etikedo maksimuma larĝo | 190mm |

| Botela diametro | 30-100mm |

| Etikedo interna diametro | 76.2mm |

| Etikedo ekstera diametro | Maksimuma330mm |

| Skiza grandeco | L2000 × W700 × 1400mm |

| Aerfonto | 4-6KG 30L / Min |

| Uzante potencon | 220V 50HZ 1200W |

Produkta Karakterizaĵo

1, Auto circumferential compensation - use of a vision system to detect the diameter variation of a bottle and make compensation to maintain relative consistence of the spacing between the labels on the bottle circumference.

2, Stable capacity at 60 bpm (dual label with bottle orientation)

3, 3-rollers holding of bottle for rotation and labeling to ensure alignment precision. Position accuracy up to ±0.8mm.

4, Various optional online coding devices including hot-stamping, inkjet, laser, and thermal transfer etc., for synchronized date/batch number coding.

5, Status information of peripheral devices can be integrated into the control panel of the system for each control.

6, Various inspection devices available for detection of missing label, wrong label, double label, bad alignment, missing code, and bad coding etc., to ensure high quality output from the system.

7, User-friendly interface with easy-to-use touch panel, comprehensive help menus, and fault indication etc.

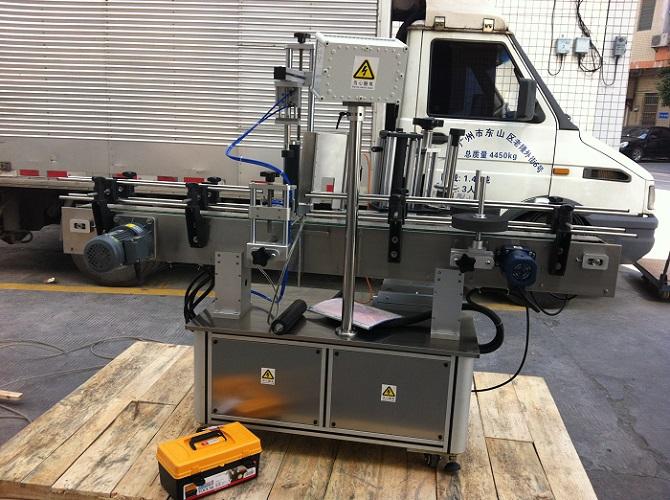

Maŝina foto

Etikedo: dorlotbestbotela etikedmaŝino, envolvi etikedaplikilon